The simplest method of starting a three-phase pump motor is by closing a contactor and allowing the motor to start at full voltage, or “across-the-line,” as it is called. However, when a pump motor is started at its full-rated voltage, the current drawn by the motor will be as high as six to eight times its normal full-load running amps for a short period of time while the motor accelerates to speed. Referred to as a “locked rotor condition,” this surge can cause a momentary voltage drop in the motor circuit that can dim lights, affect other electrical equipment and possibly overload distribution transformers. Because the effect increases with the size of the motor, electrical utilities will often limit the size of a motor that can be started “across the line” to protect their distribution system.

Additionally, starting a large pump motor at full voltage may cause water hammer in the piping system or may damage the pump due to high torque. For these reasons, it may be advantageous to start a pump motor slowly, using one of the following soft start techniques. Although soft starters are available for both single- and three-phase motors, this article will focus on three-phase starters.

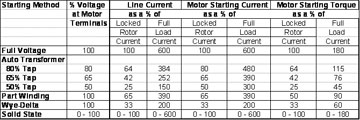

This table shows the relationship between line current, motor current and motor torque for the different types of starting methods.

Franklin Electric makes the following recommendation for using autotransformer starters with its motors: “If the pump cable length is less than 50 percent of the maximum allowable, either the 65 percent or 80 percent taps can be used. When the pump cable length is more than 50 percent of the allowable, only the 80 percent tap should be used.” This restriction is necessary due to an inherent voltage drop in the cable. Franklin’s maximum cable length charts are based on a 5 percent voltage drop at the motor. By itself, this 5 percent drop will reduce the starting current 20 percent below what it would be with the rated voltage and will reduce the starting torque 36 percent below what it would be. This reduction in starting current on some applications might be enough to preclude the need for a reduced voltage starter.

The autotransformer starter uses several voltage taps, multiple contactors and a timer to switch from one of the reduced voltage taps to full voltage several seconds after starting.

In the “Delta” configuration, the windings are wired in the normal way producing full torque and current draw. The transition from “Wye” to “Delta” is made using three contactors and a timer. During this transition, the motor is taken offline for an instant to avoid short-circuiting the contactors. Consequently, Wye-Delta starters are typically “Open Transition” types. There are some closed transition Wye-Delta starters available on special order, but the circuitry required to make them “closed transition” makes them cost-prohibitive.

It may be advantageous to start a pump motor slowly, using a soft start technique.

The final starter type is solid state-these starters utilize solid state devices called Silicon Controlled Rectifiers (SCRs) to decrease the motor voltage according to user defined parameters and can be used with standard induction motors. In the case of water-cooled, submersible motors, the soft starter has to be programmed to ramp up the motor to speed within the time period specified by the motor manufacturer (usually within three seconds). The in-rush current can be reduced to less than 50 percent of full voltage start amps (locked rotor amps), and the starting torque can be controlled to closely replicate the starting torque requirements of the pump, reducing mechanical stress on the system. Soft starts have become very reliable, and the cost is falling to the point that they are an attractive alternative to electro-mechanical reduced voltage starters. Also, variable frequency drives (VFDs) have soft-start capabilities and have become more affordable.

To summarize, if the utility can provide enough power to your motor for a full-voltage (across the line) start, most people go that way because it is cheaper. Sometimes, however, the utility does not have enough capacity to accommodate the in-rush starting current of a large motor and may ask you to provide a reduced current starter. If you have a conventionally wound motor, your choices are auto-transformer or solid-state soft start. If you need a new motor, you can buy one that is wound for Wye-Delta or part-winding starts, depending on your preference.

Next month we will begin a three-part series on variable frequency drives. Till then … ND

Report Abusive Comment