Anyone who has sat through a high school science class may remember the term “osmosis.” This process was first described by a French scientist in 1748, who noted that water spontaneously diffused through a pig bladder membrane into alcohol.

More than 200 years later, a modification of this process, known as “reverse osmosis,” allows people throughout the world to affordably convert undesirable water into water that is virtually free of aesthetic or health contaminants. Reverse osmosis systems can be found providing treated water from the kitchen counter in a private residence, to installations used in manned spacecraft.

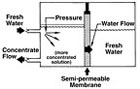

Here are the basics of how the process works: A semi-permeable membrane, whether it's a cell wall or pig bladder, is selective about what it allows to pass through. It generally allows water to pass through easily while limiting the passage of other contaminants. Water typically will be present on both sides of the membrane, with each side having a different concentration of dissolved minerals.

Since the water in the less-concentrated solution seeks to dilute the more-concentrated solution, water will pass through the membrane from the side of lower concentration to the side of greater concentration.

Eventually, osmotic pressure, or the difference in the two water levels, will become great enough to counter the diffusion process and each side will be equal.

Semi-permeable membranes have come a long way from the natural pig bladders used in the earlier osmosis experiments. Before the 1960s, these membranes were too inefficient, expensive and unreliable for practical applications outside the laboratory.

Modern advances in synthetic materials generally have solved these problems, allowing membranes to be highly efficient at rejecting contaminants, while making them tough enough to withstand the greater pressures necessary for efficient operation.

Even with these advances, the “reject” water on the source side of an RO system must be flushed periodically in order to keep it from becoming so concentrated that it forms a scale on the membrane. RO systems also typically require a carbon pre-filter for the reduction of chlorine, which can damage an RO membrane, as well as a sediment pre-filter to keep fine, suspended materials in the source water from permanently clogging the membrane. Installing a water softener also may help in hard water areas.

Residential Systems

Typical countertop or under-sink residential systems are referred to as “low-pressure” RO systems since they rely primarily on the natural water pressure to make the reverse osmosis process function (see Figure 1).Countertop units typically have an unpressurized water storage tank that is maintained at atmospheric pressure.

Under-sink units typically have a presurized accumulator storage tank where the water pressure tends to increase as the tank fills. This provides sufficient pressure to get the water from the under-sink storage tank to the faucet. Unfortunately, this also creates a backpressure against the membrane, which decreases its efficiency. Some units overcome this by using a permeate pump device or unpressurized tanks with a pump to eliminate tank pressure.

Low-pressure units typically provide between 5 gallons and 20 gallons per day of water with an efficiency of 2 gallons to 4 gallons of reject water per gallon of treated water. Water purity can be as high as 98 percent. They produce treated water for a cost as low as 10 cents per gallon after maintenance, including water costs. Maintenance usually requires replacing any pre- or post-filters as required (typically one to four times per year), and the reverse osmosis membrane cartridge about once every three years to five years.

What RO Treats

RO can treat for a wide variety of health and aesthetic contaminants. Effectively designed RO equipment can treat for aesthetic contaminants that cause unpleasant taste, color or odor problems, such as a salty or soda taste caused by chlorides or sulfates.RO also can be effective for treating health contaminants such as arsenic, asbestos, atrazine (herbicides/pesticides), fluoride, lead, mercury, nitrate and radium. When using appropriate carbon pre-filtering, additional treatment also can be provided for such “volatile” contaminants as benzene, trichloroethylene, trihalomethanes and radon. Some RO equipment also is capable of treating for biological contaminants such as Cryptosporidium.

The Water Quality Association cautions, however, that while RO membranes typically remove virtually all known microorganisms and most other health contaminants, due to design considerations, they may not offer absolute microbiological protection when incorporated into a consumer drinking water system.

When looking for a product to treat for a health contaminant, care should be used to find products that have been tested and certified successfully for such purposes by an ANSI-accredited certification organization.

Reverse osmosis is a relatively recent, but very effective, application of an established scientific process. Whether it is used to meet the needs of a typical family, or the needs of an industrial operation requiring thousands of gallons per day, it can be a cost-effective way to provide the required quantity of highly treated water. With continual advances in system and membrane design that boost efficiency and reliability, RO can be expected to play a major role in water treatment for years to come.

Report Abusive Comment