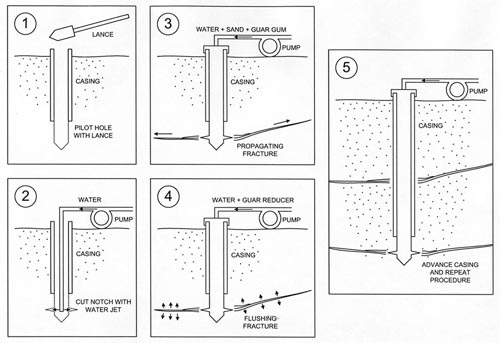

Hydraulic fracturing is performed by injecting high-pressure water or a polymer gel down a borehole to create subsurface fractures. For site remediation applications, fracture injections can be accomplished against the bottom of driven casing. Notching of the formation is done to nucleate a hydraulic fracture at the desired depth, and it is accomplished using a high-pressure water jet. This is followed by injection of the hydraulic fracturing fluid, which typically consists of a mixture of water-based gel and sand or other proppant. Additional fracture wells are drilled at adjacent locations until the entire treatment zone is fractured. Hydraulic fracturing also can be accomplished in open bore bedrock wells using a straddle packer configuration. The vertical interval between fractures typically varies from three feet to five feet. Fracture propagation proceeds at a modest rate, and a single injection normally takes 10 minutes to 30 minutes. Standard equipment for hydraulic fracturing is available from the water well and petroleum industries, although the available equipment tends to be large and expensive. Therefore, scaled-down versions have been developed for site remediation.

Another variant of hydraulic fracturing involves creation of oriented vertical fractures that have been used to form permeable reactive barriers. A series of wells are drilled at intervals along a line and hydraulic injections are made sequentially so that the vertical fractures overlap to form the barrier.

Hydraulic fracturing of bedrock formations is performed either with plain water or with propping agents such as sand or ceramic beads. In soil formations, proppants almost always are used with hydraulic fracturing. To keep the proppant suspended, special mixers and agitators are used along with a thickening agent, usually guar gum gel. The gel contains an enzyme that is designed to break down the gel to a fluid viscosity similar to water within 12 hours to 24 hours after injection. This facilitates flushing of the guar gum after the fracture is formed to assure its permeability. Liquid or granular supplements can be injected into the formation along with the pressurized fracturing fluid to complement various in situ remediation processes.

For site remediation, hydraulic fracturing has been applied in the vadose, saturated and perched hydrogeologic zones. For permeability enhancement, the technique has been effectively applied in cohesive soils such as clays, interbedded silt and clay and saprolite. In the water well and petroleum industries, hydraulic fracturing also is used effectively in bedrock. A few applications of hydraulic fracturing in sedimentary rock have been reported for site remediation.

Report Abusive Comment