During the last few articles, we laid the groundwork for pump selection by showing how to determine the amount of water needed in terms of gallons per minute, and the pressure required in terms of psi or feet of head, to satisfy the requirements of a job. This month and next, we will go into the actual pump selection process, how to read pump curves and charts, and how to select the right pump.

Generally speaking, selecting a pump is a three-step process. First, determine the pumping requirements of the job as we did in the last few articles. Second, decide which brand and type of pump (jet pump or submersible) to use. Then go to the catalogs and select a pump.

Which brand - There are a lot of very good pumps out there. In truth, you really cannot go too far wrong with any of them. Most will perform up to their curves and provide reliable service for a number of years.

Jet pump or submersible - As a rule of thumb, if most of the pumps in your area are jet pumps, install a jet. If most of them are subs, go with a sub. If there isn't a clear-cut pump of choice in the area, you should consider several other factors:

1) Jet pumps are located above ground which makes them easy to service; so easy, in fact, that many home owners will do their own service work. Not good.

2) In terms of pump purchase price, when you consider that a 1/2-Hp sub performs about the same as a 1-Hp jet, the pumps cost about the same. However, when the cost of the pump cable is thrown in (with a sub the cable is longer and possibly larger since it runs down the well to the pump), the jet could be cheaper.

3) Jets usually are the pumps of choice when the pumping level is 25 feet or less. Jets can work down to 200 feet, but since 50 percent or more of their power goes into recirculating the water through the jet nozzle to provide the lift, they are not as efficient as subs, so it will cost the homeowner more money in electricity to pump with a jet. The deeper the well, the more the balance swings over to subs.

4) If terrain or overhead obstructions make it difficult to get a pump rig to the well head, a jet may be your only choice.

Personally, I would go with a sub if the pumping level is deeper than 25 feet. If you know that some of your competition is bidding a jet, but you want to bid a sub, offer a jet as an alternative and sell your customer up to the sub for its added efficiency.

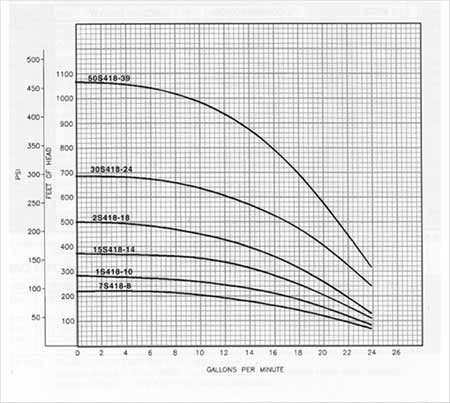

Performance curves verses performance charts - Most pump manufacturers present their performance information for submersible pumps in the form of performance curves and performance charts. We will get into performance charts next month.

The six pumps on this curve all use the same impeller and diffuser assemblies, but they differ in the number of stages (impeller/diffuser sets) and the horsepower it takes to drive them. The more stages, the more pressure the pump will provide. The first number of the model number represents the horsepower, and the last number is the number of stages. To use a curve like this, select the pump that has a curve above the operating point needed for your application.

Let's say you need a pump that provides 20 gpm at 100 psi. Move up the 20-gpm line in to the 231-feet/100-psi line going across. As you see, this operating point is just above the 1 1/2-Hp pump curve. Any pump at or above the operating point will do, so you would normally use the 2-Hp pump. Don't be tempted to choose the 1 1/2-Hp pump unless your operating point calculations were very conservative. The 3- and 5-Hp pumps would work but, for this application, would be over kill.

If you did your flow and pressure determinations conservatively, you might get away with the 11/2 Hp pump, but over the years, performance will drop off, and your system no longer will be doing the job it was designed to do. In a competitive situation where you think you are up against a 1 1/2-Hp bid, offer the 1 1/2-Hp pump as an option.

Using the information we determined in the last four articles on flow and pressure, let's find a pump that will provide 15 gpm at 98 psi (225.5 feet of head). Referring to Figure 1, draw a line up for 15 gpm and another over for 100 psi/225 feet of head. Where they cross is your operating point and it falls just below the 1-Hp pump curve. In this case, the 1-Hp pump is perfect for the job.

Next month, we will look at pump performance charts for submersible and jet pumps.

Report Abusive Comment