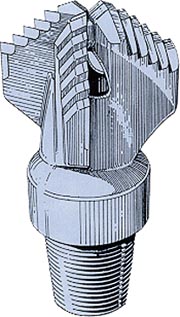

Drag Bits - Some of our most experienced and knowledgeable drillers think that a roller cone bit is the best bit for drilling sands and clays. A roller cone bit generally is for consolidated formations. Drag bits are for sands and clays.

Sticky Clay - My best recommendation is to use drag bits when drilling in sticky clays. I usually recommend the client weld a ring around the bit, but no larger than the outer cutting edge of the bit. This keeps the bit from cutting a larger hole (while rotating and not drilling). When pulling out of the hole, it cuts any clay rings (boots) and drops them to the bottom of the hole. This way the casing and gravel will go to the bottom (minus the clay that fell to the bottom). I usually over-drill the hole to allow for clays that fall to the bottom.

Stabilizer? - If not using a stabilizer, I use a bit with long reaming sides (8 inch to 12 inch minimum). This acts as a short stabilizer, preventing doglegs (deviations) in the hole. This way, when the casing is run, it will not stop at a dogleg. Many times a driller will think the hole has caved in but it is usually a dogleg.

If using a stabilizer, always try to have the bit as near to the stabilizer ribs as possible. This prevents the reduced up hole velocity between the bit and stabilizer, which causes balling.

Shovel - Another idea indirectly related to bits is the cuttings shovel. I recommend cutting small 1/4-inch holes in the shovel (like a sieve) to reduce the suction, to assist with leaving the mud in the pit and making the cuttings both lighter and dryer. Try it - you'll like it.

Experience - There are several excellent drilling schools but they only teach from what's in books - not experience. Much of what I teach is experience and that cannot be found in any books. I get many ideas from other drillers I meet in my travels and pass them along to others.

Just Ask - My most important recommendation: when you have a drilling question, problem or are about to lose your drill string, don't give up. Call a Master Certified Ground Water Contractor (MGWC). Any of our nearly 70 MGWCs will be happy to assist you - at no charge - by telephone. If you don't know one, call the National Ground Water Association at 1-800-551-7379; they will provide you with several leads. If you want to make more profits and fewer mistakes, contract a qualified drilling consultant. They can save you thousands of dollars which means future profits for you.

Report Abusive Comment