To understand how electricity causes an electric motor to turn, and to understand the difference between single- and three-phase power, let us relate electric motors to a water wheel. Picture a water wheel next to a waterfall. This particular wheel has just one cup on it that fills with water whenever it is positioned under the waterfall. The weight of the water in the cup causes the wheel to turn. The wheel has just enough momentum to complete one revolution but is kept turning by the re-filling of the cup.

A single-cup water wheel is like a single-phase electric motor. They work fine for small jobs, which don't take much inertia to get them spinning or which aren't pulling too much of a load, but getting all your energy input only once per revolution isn't the most efficient way to transfer energy.

Three-phase power, on the other hand, is like a water wheel with three cups spaced equally around the wheel. Let's call the cups L1, L2 and L3. As the wheel makes its way around completing one revolution, it gets boosted three times, instead of just once. It doesn't spin any faster, but it is easier to get it spinning in the first place (more torque), and it is more efficient because more of the water is being used to make the wheel turn.

In an electric motor, electricity is the water, the cups are the stator and the wheel is the armature. A single-phase motor gets one “cup” of electricity per revolution, and a three-phase motor gets three. Three “cups” per revolution is a much more efficient way to get an armature spinning, and to keep it spinning. That is why large motors are three-phase.

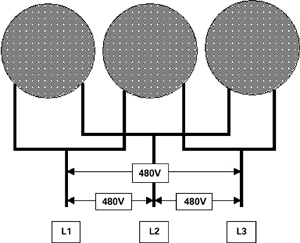

Transformers - Understanding how the utilities deliver three-phase power to end users helps us understand some of the electric motor failure modes. Whether the power is generated by nuclear energy, hydro, steam, natural gas, oil, coal or wind, the utilities use three-phase generators. They deliver the three-phase power to the grid at very high voltages for transmission efficiencies. To bring it down to a usable voltage like 240 volts or 480 volts, they use transformers, usually a separate one on each phase.

Unbalance can occur when the loads on the three legs are not equal. For example, say you have a three-phase submersible pump on your farm. You have a three-phase distribution panel where the various loads are connected. Besides the pump, you have several large single-phase loads, an air compressor, a welder and an electric range in the house. Any or all of these loads can be taken from any of the three legs, L1/L2, L2/L3 or L3/L1. If one of the legs is carrying more current than the other two legs, its voltage will be lower than the others, and you have an out-of-balance condition that might damage your submersible pump motor. This damage occurs because one of the three motor windings in an unbalanced condition will carry more load than the others and overheat. A slightly unbalanced condition will cause a slight overheating of the windings and may shorten the life of the motor. A severely unbalanced condition will definitely shorten the life of the motor and may cause an immediate failure depending on the severity of the unbalance and the load on the motor.

Franklin Electric recommends not exceeding 10 percent current unbalance at the rated input motor load and 5 percent at service factor load for their motors. If your power is more out of balance than this, you still may be able to operate a three-phase motor by over-sizing the motor such that the overloaded winding is not carrying more load than it was designed to carry. For instance, a 10-HP pump operating on three-phase power, which is 15 percent out-of-balance, may run just fine with a 15-HP motor. Consult your motor manufacturer for a recommendation for your particular situation. We will talk more about dealing with unbalanced power in the coming months.

There is another three-phase configuration called “open delta” that uses two transformers instead of three. Open delta power is harder to balance than conventional three-phase power, so extra care must be taken to ensure that the motor will not be damaged. For a more complete description of open delta, see Franklin Electric's “Submersible Motor Application Manual.” If you do not have a copy, call Franklin at 800-348-2420. Another good source for information on three-phase power is the “Electrical Engineering Pocket Handbook,” published by the Electrical Apparatus Service Association; phone 314-993-2220.

Next month, we will look at phase converters, the devices we use to convert single-phase power to three-phase power. 'Til then ….

ND

Report Abusive Comment