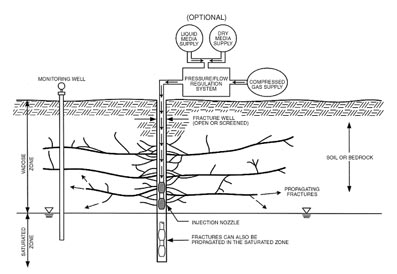

The source of compressed gas typically is high-pressure storage cylinders. Formations are fractured sequentially by moving the injection nozzle vertically within the borehole or well, and then moving the injection nozzle to adjacent locations until the entire treatment zone is fractured. The vertical interval between fractures varies from 6 inches to 3 feet, although 2 feet is typical. Fracture propagation is relatively rapid – approximately 6 feet per second – and a single injection event lasts about 15 seconds to 20 seconds. Pneumatic fracturing equipment normally is trailer-mounted and relatively portable. Accessory equipment is available to inject a wide variety of liquid or granular supplements into the formation along with a pressurized gas to complement various remediation technologies.

Pneumatic fracturing can be distinguished from two other technologies that also involve the injection of gas into geologic formations – air sparging and air injection. Both of these technologies force air through existing pores and fractures in the formation. In contrast, pneumatic fracturing dilates the formation and creates new or expanded pathways for transport.

Pneumatic fracturing has been applied in vadose, saturated and perched ground water zones. For permeability enhancement, the technique has been applied in fine sands, silty sands, silts, clays and various soil mixtures containing silt and clay, including saprolites. The permeability of sedimentary rock formations, including mudstones, siltstones, sandstones and shale, also has been enhanced with pneumatic fracturing. When used for injection of liquid, granular or gaseous supplements, essentially all soil grain sizes and some bedrock types are considered treatable with pneumatic fracturing, including sands, gravels and mixtures.

Report Abusive Comment