Raising Diamonds

Diamond crystals can be synthetically grown in a wide variety of qualities, shapes and sizes. Synthetic diamond has replaced natural diamond in virtually all construction applications because of this ability to tailor-make the diamond for the specific application. Diamond also is grown to a specific toughness, which generally increases as the crystal size decreases. The size of the diamond crystals, commonly referred to as mesh size, determines the number of diamond cutting points exposed on the surface of a saw blade. In general, larger mesh size diamond is used for cutting softer materials while smaller mesh size diamond is used for cutting harder materials. However, there are many interrelated factors to consider.

Diamond Concentration

The number of crystals per volume, or diamond concentration, also affects the cutting performance of the diamond tool. Diamond concentration, commonly referred to as CON, is a measure of the amount of diamond contained in a segment based upon volume. A common reference point is 100 CON, which equals 72 carats per cubic inch. Diamond concentration for construction tools is typically in the range of 15-50 CON. Increasing the diamond concentration by providing more cutting points will make the bond act harder while also increasing diamond tool life.

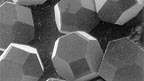

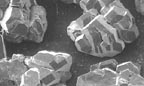

Shape and Size

Diamond shapes can vary from tough blocky cubo-octahedral crystals (Figure 1) to more friable crystals with less well-defined geometry (Figure 2). Diamond crystals with blocky shapes and sharp edges generally are better suited for stone and construction applications. The blocky shape provides greater resistance to fracturing, and thus provides the maximum number of cutting points and minimum surface contact. This has a direct impact in a lower horsepower requirement for the machine and maximizing the life for the tool. Lower grade diamond is less costly and generally has more irregularly shaped and angular crystals and is more suited for less severe applications.The exposure, or height, of diamond protrusion influences the depth of cut of each crystal, and subsequently, the potential material removal rate. You will find that larger diamond crystals and greater diamond protrusion will result in a potentially faster material removal rate when there is enough horsepower available.

Specifying the proper mesh size is the job of the diamond tool manufacturer. Producing the right number of cutting points can help to maximize the life of the tool and minimize the machine power requirements.

Diamond Impact Strength Examined

All diamond is not the same, and this is especially true for the strength of diamonds used in construction applications. The ability of a diamond to withstand an impact load is typically referred to as diamond impact strength. Other diamond-related factors, such as crystal shape, size, inclusions and the distribution of these crystal properties, play a role in the impact strength, as well.Impact strength can be measured and is commonly referred to as Toughness Index (TI). In addition, crystals are also subjected to very high temperatures during manufacturing and sometimes during the cutting process. Thermal Toughness Index (TTI) is the measure of the ability of a diamond crystal to withstand thermal cycling.

The manufacturer must select the right diamond based on the tool's design, bond properties, material to be cut and machine power. These factors must be balanced by the selection of diamond grade and concentration that will provide the operator with optimum performance at a suitable cost.

In general, a greater impact strength is required for more demanding, harder-to-cut materials. However, always using higher impact strength diamond that is more expensive will not always benefit the operator. It may not improve, and may even degrade tool performance.

How Diamond Tools Work

A diamond saw blade is composed of a circular steel disk with segments containing the diamond that are attached to the outer perimeter of the blade. The diamonds are held in place by the segment, which is a specially formulated mixture of metal bond powders and diamond that have been pressed and heated in a sintering press by the manufacturer. The diamond and bond are tailor-made to the specific cutting application. The exposed diamonds on the surface of the segment do the cutting. A diamond blade cuts in a manner similar to how sand paper cuts wood. As the blade cuts, bond tails are formed that trail behind each diamond (Figure 3). This bond tail provides mechanical support for the diamond crystal. As the blade rotates through the material, the diamonds chip away at the material being cut.Contrary to a popular advertising campaign, a diamond is not forever. The exposed diamond cutting points eventually wear away, and if not for some provision to replace these cutting points, the blade or bit would soon be useless. This process actually is desired as it provides a new layer of diamond crystals to continue the cutting action.

The ideal life of a diamond starts as a whole crystal that becomes exposed through the segment bond matrix. As the blade begins to cut, a small wear-flat develops and a bond tail develops behind the diamond. Eventually, small microfractures develop, but the diamond is still cutting well. Then the diamond begins to macrofracture and eventually crushes. This is the last stage of a diamond before it experiences a popout, where the diamond literally pops out of the bond. The blade continues to work as its cutting action is taken over by the next layer of diamonds that are interspersed throughout the segment.

The metal bond matrix, which can be made of iron, cobalt, nickel, bronze or other metals in various combinations, is designed to wear away after many revolutions of the blade. Its wear rate is designed so that it will wear at a rate that will provide maximum retention of the diamond crystals and protrusion from the matrix so that they can cut. Critical factors are the bond system, material to be cut and machine parameters. The combination of diamond and bond accomplishes a number of critical functions:

- Separation and support for the diamond

- Control of the segment wear rate

- Introduction of new diamond cutting points

- Optimum diamond retention

- Distribution of the impact load of the diamond as it grinds.

Blade Design

The blade cores have slots, or gullets, which allow the blade to flex under the pressures of cutting, allow air or water to circulate, and cool the blade while helping to remove the swarf that results from the material that is being cut. All blades have center holes that vary in size, depending on the saw shaft on which they will operate.The segments that are attached to the blade must be wider than the core, otherwise the blade core will wear quickly and render the diamond blade useless. The overlap of the segment over the blade core is called side clearance and it allows the blade to turn in the cut without dragging on the sides.

The manufacturer tensions blades (sometimes called smithing) at the factory so they will run straight at the design cutting speeds. Proper tensioning allows the blade to remain flexible enough to bend slightly under the cutting pressure and snap back into position. During the manufacturing break-in, or grinding and dressing process, individual diamond crystals are exposed on the outside edge and sides of the diamond segments or rim. These exposed surface diamonds make the blade ready to cut right out of the box.

Segment Attachment

It is important for the operator to understand that different methods are utilized to attach the diamond segments to the steel core. Two of the more popular methods utilized today include brazing and laser welding.The traditional method used to attach segments to the steel core is brazing. A silver solder, placed between the segment and the core, is heated above the melting point to bond the segment to the core. The type of solder used melts at high temperatures (above 400 degrees F). This melting temperature is below the temperature a blade encounters during dry sawing, and is the reason that braze welded blades should not be operated dry.

With laser welding, the diamond segment and the steel core are fused together by a laser beam. The laser beam melts a portion of the steel core and the segment backing metal, forming a weld. This weld is stronger than either the steel core or the segment and does not melt at the higher temperatures encountered when cutting dry.

Blade Operating Speeds

Recommended operating speeds are based on blade size, equipment type and the type of material being cut. Maximum operating speeds are set by the American National Standards Institute, and are printed directly on the blade. Failure to comply with this warning is dangerous and can result in injury or death.The operating speeds for cutting concrete have been found to be best around 10,000 sfpm (surface feet per minute) or the surface speed of the diamond cutting segments on the periphery of the blade. The diamond blade operating speeds (Figure 4) have been developed to provide operators with recommended operating speeds and maximum safe speeds in terms of rpm. Attaching a tachometer to the machine's blade shaft can check machine speeds.

It is important for the operator to use the correct operating conditions to maximize blade performance. For optimum blade life and cutting speed, the actual operating speed will most likely have to be adjusted for the type of aggregate and the amount of steel encountered. In general, higher operating speeds make the blade act harder and tend to lengthen blade life, but slow the cutting. Decreasing blade speed will make the blade act softer, but blade life also will decrease.

When in doubt about the correct operating speed for a particular material, it is better to choose a lower speed rather than a higher speed. Once the blade is cutting well, the speed can be increased to optimize life of the diamond blade.

Depth of Cut

The depth of cut should be adjusted so that a forward speed for a saw of 8 fpm to 10 fpm (feet per minute) can be maintained while cutting concrete. Coolant water or some other coolant must be used to cool most diamond blades. If not enough water is used, the swarf will not be removed from the cut quickly. This is a common, but not the main cause, of undercutting where the abrasive particles from the cut wear away the steel core just below where the diamond segment is attached to the steel core. Without sufficient water, the core also will overheat, causing cracks and premature loss of segments. The water flow for cooling saw blades should be between 1.3 gal./min. and 2.6 gal./min.Tensioning

Tensioning is designed to keep blades from distorting at high speeds. The blade actually is manufactured in the form of a dish that will straighten when the blade is rotated at optimum speed. The dishing is small, in the order of 0.0005 inch per inch of diameter. The tensioning can be accomplished by a mechanical roller tensioning machine or a hammer smith. This process is especially critical for blades of larger diameter.If the design speed is not achieved, the blade will tend to wander as cutting begins. When a blade is said to be out of tension, the amount of dish is not correct. Such a blade would wobble from side to side while out of the cut and it wanders when placed in the cut. An out-of-tension blade cannot be made to cut a straight line.

Machine Drive Power

Another factor to consider when optimizing the cost-effective use of any blade is the amount of power available to a blade. This also has an effect upon tool performance. Operating a machine with less power than is required can result in blades that will polish or glaze over, resulting in slow cutting speeds.Machine power requirements for typical concrete cutting machines are:

Application Power Requirements

Core Drills 2 to 20 horsepower

Flat Saws 8 to 100 horsepower

Wall Saws 10 to 35 horsepower

Wire Saws 10 to 50 horsepowerIn order for a saw blade manufacturer to provide the proper cutting tool, it is necessary to know the maximum horsepower of the machine. Generally, but not always, blades with soft bond segments will break down faster if used with high-horsepower equipment. On the other hand, blades with hard bond segments cut better when used on high-horsepower equipment.

Diamond cutting tools require that pressure be applied for maximum performance. Sufficient pressure must be applied to maintain sharp cutting crystals. If too little pressure is applied, the diamond crystals are likely to become dull and polish. Conversely, too much pressure can also damage the diamond cutting tool.

Looking Ahead

Next month, part two of this article will address materials to be cut, field performance and troubleshooting.

Report Abusive Comment