At about the same time, he pushed a bucket upside-down into water and when he pulled the bucket out, he noticed that it wasn't completely wet inside. Those two events got Ctesibius to thinking about air pressure and water pressure. The bit about air pressure is significant because up until then, people basically viewed air as nothingness. They understood wind but didn't see air itself as a real thing. So considering when it was invented - before much was understood about hydraulics, Ctesibius' force pump was quite complex and represented a major advancement in water delivery.

While the apparatus was quite complex for its time, the principle of the force pump is rather simple: Water flows into a one-way cylinder where it is forced out by a piston through another one-way valve. It then flows into a delivery pipe. In order to take full advantage of this type of drive, a second cylinder is added alongside the first, and both of their pistons were moved by means of a connecting rods attached to opposite ends of a single lever. In order to even out the discharge and to optimize efficiency, the cylinders were 180 degrees out of cycle from each other. During the upward movement of the piston, the cylinder functions as a suction pump, bringing water in through a rise pipe. During the downward movement, the piston forces the water that has been sucked from the pump cylinder into a head pipe.

Force pumps primarily were composed of bronze. There were, however, cases where wood was used in order to save expenses. Improvements to the original force pump include a swiveling nozzle and piston gaskets to improve efficiency and durability.

A number of factors determined the capacity of the force pump. The cylinders' diameter and the length of the piston stroke determined the displacement. The total discharge is dependent upon the number cycles, which are determined to have been between 44 and 60 cycles per minute. Also, the pump's efficiency affected the discharge capabilities. As for the size of the cylinders, bronze could be made to any specification, while a wood cylinder could only be as big as the thickest tree in the area.

The force pump was used in many applications, including small-scale extraction from wells for irrigation and as a bilge pump for boats. There also are records of the force pump being incorporated into fire extinguishers and water jet systems for cleaning high vaulted ceilings. ND

The Water Clock

In today's world, the importance of time - the exact time - cannot be overstated; the clock pretty much dictates nearly every aspect of our lives. Extremely rare are the circumstances when time is of little or no consideration. For this, we can thank - blame, really - our good friend Ctesibius.Up until about 270 B.C., peoples' concern with time primarily dealt with night and day and season of the year. One exception was when a person had to appear in court. When defending yourself in court, you were given a certain amount of time to present your case. The device used to monitor the elapsed time was called a clepsydra and it basically was a jar with a hole in it. A measured amount of water was placed in the jar and you had until the water ran out. If you were caught driving your chariot in the carpool lane, you'd get a couple ounces; if you were accused of murder, you got maybe half a gallon.

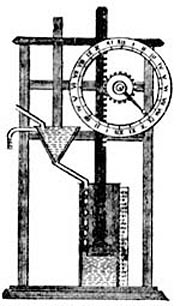

Ctesibius wanted to take this device that marked the end of a given time to the next level so that it could mark time continuously (a clock). His breakthrough came when he realized that the water in the clepsydra dripped out faster when it was full than when it became empty. His solution was to keep the jar constantly full. He accomplished this by using a second container that supplied the original jar, that would then drip at a constant rate into a third container. This third container featured a float, which, as it rose with the water level, moved the gears on the clock face.

Mechanical clocks featuring weights instead of water were made in the 1300s. But it wasn't until 1657, when Christiaan Huygens demonstrated how a pendulum could regulate a clock, that the guts for the modern clock finally were established. That's when we first had a mechanical clock that was more accurate than Ctesibius' water clock - invented nearly 2,000 years previously.

Report Abusive Comment