We will begin with a review of how to determine peak demand. Then, we will discuss several options for meeting peak demand from a slow producing well. And finally, we will describe in detail a two-pump booster system.

Determining peak demand - A practical and generally accepted rule for determining the peak demand in single-family residential applications is as follows: The capacity of the system, in gallons per minute, should equal the number of fixtures served by the system, but not be less than the peak demand for the largest single fixture. For this purpose, fixtures are defined as outlets, such as washing machines, dishwashers, toilets, sinks or outside faucets.

For example, a home with two bathrooms, each having a tub, toilet and sink, a kitchen with a sink and dishwasher, and two outside hose bibs would have a peak demand of 10 gpm.

Converting peak demand into storage required - If the rate of flow required during the demand period exceeds the maximum rate at which water can be drawn from the well, the difference must be made up by storage. The amount of storage required will depend on how long that demand lasts. As mentioned in last month's article, the Water Systems Council recommends providing for peak demand for a minimum of seven minutes. Most contractors use a longer period of peak demand time - up to one hour - unless they are providing a minimal system for competitive or other reasons. Using a period of one hour for this exercise, the total capacity of the system would be 600 gallons (10 gpm times 60 minutes = 600 gallons).

Local codes may govern the amount of storage needed. Some areas have regulations regarding minimum well production, and others require a certain amount of storage for fire protection. These standards should be your first guide as to the size of storage system to provide.

Storage options - Three options are available to meet the requirements of additional storage: using water stored in the well, increasing the amount of drawdown available from the pressure tank, as described last month, and using a non-pressurized storage tank with a booster pump.

Using the pressure tank for storage - We covered this technique in detail last month, so we'll only hit the highlights in this article by way of review.

When the well recovery rate is close to the peak demand rate, using the pressure tank to make up the difference may be the best choice. A pressure tank normally is sized to provide a minimum of one minute run time for the pump. In other words, a 10-gpm pump should have a pressure tank with at least 10 gallons of drawdown available. This allows the pump to cool between cycles, extending the life of the motor. Any pressure tank drawdown capacity beyond that needed to protect the pump can be counted as storage capacity. A small increase in capacity can be realized by using lower cut-in/cut-out pressures or by increasing the spread between the cut-in and cut-out pressures.

Do not, however, increase the spread between the cut-in and cut-out pressures to a point where the drawdown exceeds the capacity of the water chamber (diaphragm or bladder). Stretching the diaphragm or bladder will shorten its life. The tank manufacturer's literature lists the total capacity of the water chamber. Additionally, increasing the pressure differential in a residential system may not be acceptable to your customer. Too much differential may make an annoying pressure fluctuation in the shower.

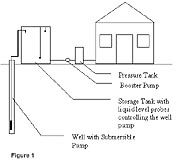

Using a separate storage tank - A storage tank, as opposed to a pressure tank, is a large non-pressurized vessel that receives water from the well for use during periods of peak demand. The use of a storage tank necessitates the use of a second pump called a booster pump and a pressure tank, sized the same way you do in a single-pump system and controlled by a pressure switch located at the pressure tank. The well pump now will be controlled by floats or sensors in the storage tank rather than by a pressure switch. One float or sensor is located at the bottom of the tank to turn the pump on, and one is located at the top of the tank to turn the pump off when the tank is full (see Figure 1 on p. 19).

Next month, we will finish the topic of booster systems with a look at pump options. 'Til then ... .

ND

Report Abusive Comment