In the slow-to-change drilling industry, new geo-thermal technology advancements now offer an exciting opportunity for drillers. New, more efficient systems are bumping-aside standard, water-sourced heat pumps, availing an entirely new market for those in the drilling industry. A shrinking landscape, higher system efficiency and a drive to meet the needs of homeowners and builders sheds light on one of the most exciting developments in the "geo" field - direct-exchange systems.

Pushing the Energy Button

Cousins Dan and Sam Bandimere readily admit that small-bore drilling for new geothermal technology has changed their lives. Though Sam operates his drilling business, Bandimere Geothermal Drilling Systems, out of the Denver area, and Dan runs his firm, EnviroGuard Drilling, out of Fort Smith, Ark., the two rarely go a day without calling each other. Invariably, the topic of conversation quickly moves to their chosen careers.“It's a field that gets more exciting by the day,” says Sam, who spent 25 very successful years as owner of a specialized drilling and grouting company, Denver Grouting Services (which he sold five years ago), and now as owner of a small-bore drilling and equipment enterprise.

Dan's been in the business for just five years. He was looking for a new career opportunity and his cousin led him to it. “There's no looking back,” says Dan, whose 15 years in the HVAC business positioned him nicely for involvement in the geo-thermal field. Drilling made up the bulk of his recent learning curve, but now he's on a steady course with his business, with solid profitability and growth.

Both Bandimeres - who own identical custom drill rigs (see the sidebar) - hold the belief that drilling should be the full focus of the business. They do not encourage those in the HVAC business to take up drilling. “This is an exciting opportunity for drillers,” emphasizes Sam Bandimere.

Glenn Bland, owner of Bland Air Conditioning and Heating in Bakersfield, Calif., has, since 1985, built his successful HVAC firm on high-efficiency solutions for customers. “Customers are quickly drawn to geothermal air conditioning and heating solutions. We've partnered with a great drilling firm near here - Consolidated Testing Laboratories - and both of our businesses have grown as a result.”

What's all the excitement about? It's called direct-exchange geothermal, or “DX geo.” DX is at the cutting edge of heat pump technology. Certified systems now are offered by two firms - ECR Technologies Inc. and American Geothermal DX.

Homeowner customers typically have a lot to say about the attributes of direct-exchange technology. Invariably, conversations swing to the incredible saving they see for energy costs. And with energy efficiencies of 400 percent to 450 percent, you would, too. Take John and Linda Cavanaugh, for instance. John worked in the electric utility industry for 26 years, and Linda was once a professional energy auditor. You might say they have a rather unique perspective on the responsible use of energy. Two years before they built their 2,600-square-foot home in coastal Rye, N.H., the Cavanaughs set out on a research path to make their home as energy efficient as possible. They scrutinized construction style, windows and roofing, insulation and HVAC.

One of the key choices they made - requiring a 50 percent higher up-front cost than a standard HVAC system, but with relatively quick pay-back - was to install a geothermal heating and cooling system.

The ECR EarthLinked system they chose is much different than what many people consider a geothermal system to be - that being a water-sourced system that exchanges thermal energy through water in vast networks of plastic tubing. DX technology accomplishes thermal transfer with a much smaller “geo field” or “earth loop” system, so it requires a lot less disruption of the property, is ideal for retrofits, and provides higher operational efficiency. Many of these systems have drilled geo fields.

Because of their keen interest in the system, and the energy efficiency it would provide, the Cavanaughs began tracking the system's energy use for heating, cooling and domestic water once the system was in place. To do this, they placed a separate electric meter on the ECR system. Every month, in addition to carefully tracking the electrical energy required for lighting and power, they separately recorded monthly kilowatt hours coupled with degree-day measurements for comfort control and domestic hot water.

By knowing what their neighbors spend on energy to do the same job, the Cavanaughs up-charge - the difference between the cost of a standard heat pump and the system they installed - was paid for, remarkably, in less than three years (thanks, in part, to a utility rebate that subsidized the high efficiency system). During a 33-month period - February 2002 to October 2004 - the Cavanaugh's monthly charge for heating, cooling and hot water averaged just $71.90.

Five years ago, a family in Pennsylvania chose to have the geothermal heating and cooling system installed when they built their home. Now, while many of their neighbors are experiencing record high electric and gas utility bills, the homeowners are enjoying record savings. Last year, they paid only $650 (about $55 per month) for heat, air conditioning and hot water in his 3,200-square-foot home. When compared to the average $220 per month that his neighbors are paying for these services in homes of about the same size, a quick calculation reveals that they are saving more than 70 percent on utility expenses. It's typical of what they've seen during the past several years. "Our previous home had electric baseboard heat and window air conditioning units. It was terribly inefficient, and rather uncomfortable at that,” says the homeowner. "Today, the comfort is seamless and smooth year-round and entirely reliable. We're delighted with the geothermal system.

“We decided before moving in that we would separately monitor the system's energy use,” he adds. “For four years now, we've seen how it gives us four to five units of energy for every unit of electricity it consumes.”

DX geothermal systems tap the earth's abundant energy in the most efficient means possible, through direct contact with the earth. A direct-exchange system harvests heat directly from the earth, which maintains a constant temperature of about 50 degrees F in New Hampshire, and 52 degrees F in central Pennsylvania. While air-source heat pumps rely on a wide range of ambient air temperatures, the earth's constant temperature provides a much more favorable source for heating and cooling.

The 3,200 square-foot home in Pennsylvania required a 31⁄2-ton (42,000 BTU), 14-loop DX system. The earth loops for the system required that 14 2 1/2-inch diameter holes be drilled at 45-degree angles to depths of 50 feet.

Pay Dirt

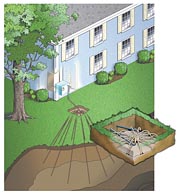

According to Sam Bandimere, a common drilling technique for the ground loop configurations is the diagonal method, which disturbs the least amount of earth. For homes where ground space is limited, or especially for existing homes with mature landscaping, this configuration is ideal because all of the small-diameter drilling takes place from a shallow, 6-square-foot pit, with drill holes radiating outward and down at an angle from the base of the pit. (See Figure 1.)"Most geothermal systems operate at ranges of 250 percent to 350 percent efficiency. That means the systems supply up to three-and-a-half units of heat for every unit of electrical energy required to operate it," says Bland, who's in-stalled many types of geothermal heating and cooling systems for more than 30 years. “With the variety of options available for installation of the earth field, and the highest operational system efficiencies, DX is a great choice for many homes or buildings.”

DX technology circulates refrigerant through highly conductive copper earth loops that are inserted into boreholes of 50-foot or 100-foot depths, then embedded in a protective thermal grout that enables direct transfer of energy with the earth. The refrigerant moves directly from the geo field to the unit's compressor with no stops or intermediate heat exchangers required, enabling efficient transfer of thermal energy.

ND

Sidebar:

The Bandimeres - Small Bore Drilling is All in the Family

Before beginning his drilling enterprise, Dan Bandimere worked many years repairing refrigeration units for the trucking industry. His cousin Sam Bandimere - who encouraged Dan to enter the business - is an entrepreneur who spent more than 25 years developing a specialized drilling and grouting company, Denver Grouting Services, which he grew into a global firm before he sold it in 1996.Dan and Sam now own identical custom drill rigs for installing ground source heat pump loops. That's because Sam's entrepreneurial drive led him simultaneously into the rig-building business. He begins with a Volvo skid steer loader and equips it with a TEI Rock Drills mast and a Chem-Grout grout plant for geothermal grouting. “It's a versatile, sturdy package that couples-up with a customized gooseneck trailer,” says Sam. To haul it, he suggests a minimum 1-ton dual-axle pickup, or larger.

Both Sam and Dan appreciate the ability to be quickly rigged for drilling, or to disengage the drilling system in a matter of minutes, allowing the power unit to be used for other purposes with other attachments. Sam's TEI drill is a TE300HT, a top-hammer drill that has rotary or rotary/percussion capabilities.

They use 10-foot drill rods that take carbide rotary drag bits or percussion button bits. The drill head flushes drill cuttings with air, water, polymers, bentonite or just about any flushing method available today with flow capabilities of up to 185 cfm or 20 gpm. They have adapters that permit casing holes with either a 3-inch I.D. or 2-inch I.D. casings. The 3-inch casing allows for inner rod drilling beyond depths of casing requirements. The 2-inch casing only allows for total depth drilling (typically 100 ft.); they then slide the copper loop inside and retract the casing, leaving the loop in place.

It's rare that either Sam or Dan need casings, though. The only time they need them is when they start a hole in sand or gravel, but usually by the time they get to 30 feet, the overburden pressures are sufficient to hold open the holes. Their drills have the capability of reaching depths of 100 feet - the typical depth required for the loops. Their drill rigs typically will install three loops per day. But with mobilization, loop work and line set installations, the average is two loops per day from one jobsite to the next.

Together, Dan and Sam provide a list of key points that demonstrate the uniqueness of their approach to small-bore drilling:

Drill mast can be pivoted left, right, forward and backwards up to 45 degrees. This permits the containment of inserted loops, and the refrigerant distribution manifold, within a 3- to 4-foot diameter pit within 10 feet of the structure. That's a very small footprint, and permits minimal impact on the land.

Their choice of drilling equipment that's designed for quick connection to a skid steer loader or back hoe. Equipment related to the drilling and grouting operation fit easily on a custom-built trailer designed by Sam, making it a one truck/trailer operation.

Their top-hammer approach is ideally suited to meet the various drilling conditions that they typically encounter. “A down-hole hammer is more efficient if all you do is drill rock, but the geologic conditions I encounter in the large geographic region I cover makes the top-hammer approach more suitable,” says Dan.

Both Sam and Dan are excited about the future. On their wish list: they'd like to start a Geothermal Drillers Association. Interested? They encourage you to call.

Sam is convinced that the geothermal drilling industry is today where the directional drilling industry was 20 years ago. It's in its infancy now. But, he adds, “What an opportunity for drillers who are looking for something new.”

Report Abusive Comment