Iron, manganese and hydrogen sulfide can be found in well water, particularly as aquifer levels drop. Iron bacteria. Photo courtesy of the USGS.

I’m sure you have seen the yellow, brown or black stains on fixtures in homes – something seen as a big nuisance can lead to big profits for well drilling and pump installation companies.

As aquifer levels continue to drop, the concentration of minerals increase, causing problems well owners may not have had before, such as staining, foul odors, etc. This stands as an opportunity for well drilling and/or pump service contractors to solve a problem for their customers – and add extra revenue for their companies at the same time.

Here are a few common problems that plague well water and how to diagnose them.

Iron

When iron is present in water, we see the red stains associated with it. Often, we see a slime build up, bad taste, and sometimes even a foul odor.Iron is present in water in three forms.

- Dissolved iron is in solution and appears clear until oxidized by air. This type of iron also is referred to as ferrous iron.

- Visible (or precipitated) iron is in suspension due to its exposure to oxygen. This type of iron is referred to as ferric iron.

- Iron bacteria is a general term given to bacteria that grow like algae in the water. There are many different forms of this bacteria, however, they are harmless to human health. Iron bacteria is a slimy, sticky substance, usually stained rusty red.

Iron is measured by a simple test, and is represented in parts per million (ppm) or milligrams per litter (mg/L). A ppm is the same thing as mg/L. Remember it takes 17.1 ppm to equal 1 grain per gallon of hardness. As little as 0.3 ppm of iron is sufficient to cause staining in fixtures and appliances.

Manganese

Manganese seldom is found alone in water, however, it frequently is found in water containing iron. Manganese is considered to be a close relative of iron, since it occurs in the same form as iron. But, unlike iron, manganese stains are an objectionable black or brown, and as little as 0.05 ppm is enough to start the staining process. Manganese is considered by most to be more difficult to remove because it has slower oxidation properties.Hydrogen Sulfide

Hydrogen sulfide (sulfur)is a gas present in some waters. Usually, there is no doubt as to when it is present due to its offensive odor, which can be detected as low as 0.1 ppm. Besides the odor, hydrogen sulfide also causes a black stain and can be corrosive. Sulfur must be treated like iron or manganese, and be removed through some type of oxidation treatment.Because conventional water softeners cannot backwash fast enough to eliminate the precipitated iron, manganese or sulfur, oxidizing filters usually are applied.

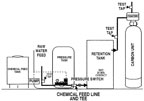

Example of a chlorination/de-chlorination system.

Types of Oxidation Filters

Automatic greensand filters with potassium permanganate used as the regenerate:Greensand filters usually are applied when the iron exceeds 1 ppm, manganese or hydrogen sulfide is present. As the water passes by the greensand, the iron or sulfur is oxidized, and the oxidation precipitates the contaminant. Greensand has a tremendous amount of oxygen in its structure, which is what causes the oxidation and precipitation. Once all the oxygen is used, the greensand must be regenerated with potassium permanganate.

Chlorination/de-chlorination system:

Again, this system primarily is used on larger amounts of sulfur, iron and manganese. This system involves a chemical feed pump, retention tank and a filter, usually carbon. When the pump starts, the chemical feed pump discharges a small amount of chlorine, which mixes with the water in the retention tank. To ensure proper precipitation of the contaminant, the retention tank should be sized for a 20-minute contact time for iron, and 30 minutes for manganese, using a proper pH level. From the retention tank, the water goes to the filter to remove the particles from the water.

Other Options

Remember that 0.3-ppm iron and 0.05-ppm manganese can cause staining problems. Iron needs 20 minutes of contact time, and manganese, 30 minutes, if you’re doing an oxidation-filtration method of treatment. There are other ways to remove iron and manganese from the water, such as properly sized water softeners. Be sure you don’t use an off-the-shelf water softener on problem water. You will need the right resin – meaning fine mesh. You’ll then need to set the system at maximum salting, plus add a resin cleaner feeder, installed in the brine tank. Technology has come a long way, and there are other media systems on the market today.There are many more ways to treat the water – just be sure and find a company experienced with problem water to help you; it can be very profitable for your business. Simple, easy-to-use test kits to test iron, hardness, manganese and pH are a must if you’re going to offer treatment equipment for well water. There also are multi-parameter meters to test for around 200 different parameters, or you can send a water sample to a lab or to your local health department for bacteria testing.

ND

Report Abusive Comment