|

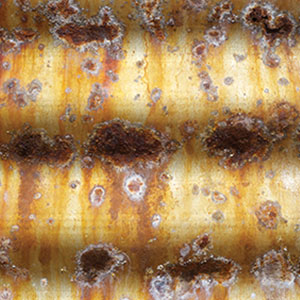

| Columnist John Schmitt says he’s seen bladder tanks rust from the outside because of their proximity to the salt tank of a water softener. Source: iStock |

One of the few drawbacks of the early bladder tanks was they were small due to the fact that they were made of stainless steel, which was and is quite expensive. This limited their use to fairly small pumps with low production rates so the motor had a long run cycle and would not “start/stop” itself to an early death.

Make no mistake, though, these tanks were a huge step forward and had a feature that we don’t think about much anymore. They could be installed in any position; this includes being so-called right-side up, upside down, or at any angle in between. With a conventional tank that our industry had used for decades, at least the smaller ones, standing straight up was the only position that really worked. Now, some larger tanks were designed to lay horizontally, but these really were few and far between compared to small tanks used in homes and farms.

After some years of making these stainless steel bladder tanks, which I think were initially called constant pressure tanks, some smart folks figured out a way to make a long-lasting tank using carbon steel. The method they came up with was to line the inside of the tank with a non-metallic material, some sort of plastic, lock it in place with a metal ring and then install the rollable bladder. The tank was then welded together and we had a pretty much corrosion proof unit. Other manufacturers began making this style tank using Fiberglas or other non-metallic material. These, too, are pretty much corrosion proof. The outside of the steel tanks was given a coat of good quality paint and we have what has become the common tank of our industry.

These tanks, no matter what their construction, did away with the old “bug-a-boo” of waterlogging. Also, due to the fact that they were pre-charged with air, a smaller tank could be used and still give the pump a good run time. This was easier on the installer, as a smaller tank was lighter and easier to handle. The Fiberglas ones were, and are, the easiest of all. Sometime space is limited in a basement, utility room or a crawl space and the smaller tanks have a big advantage there too.

This is not to say that bladder tanks are an end-all cure-all, or that they never have a problem. Although I never experienced it, a contractor friend has had serious complaints of bad tasting and smelly water using bladder-style tanks that he never had with a conventional tank. If the water from the well contained any air or gas that occurred naturally this could really foul up the system, as spitting and sputtering at assorted taps would result.

As to durability, any of the painted steel tanks would usually last a long time, which is good because most have a five year warranty. If one of these tanks is installed near the salt tank of a water softener, occasional rusting from the outside in is a problem. Salt could be spilled on the tank and, if not removed, it could corrode the carbon steel. In my career I have had a couple tanks that rusted from the outside in, not the other way around, and they were installed near a salt tank.

Lest you think these tanks were foolproof, in addition to the taste, odor and gas problems they have proven to be harder to replace than a conventional tank. If a conventional tank begins to leak or becomes filled with rust or sediment, it can be rather easily drained, removed and taken to the local recycle center, aka, the junkyard. If the bladder in a bladder tank fails, and this does happen, the only way to drain it is to drill holes into the sides and let the water gush out. I know some fellows who use a pickaxe to punch holes in the side. This is necessary, as even a small, say 44 gallon tank, is going to weigh about 400 pounds full of water and few repair men that I know can carry a tank of that weight.

Another rather rare failure of the early steel tanks was that they had a cast iron elbow at the extreme bottom. These elbows can and do corrode out and start to leak. I have had a few failures like this admittedly after many years, one even in my own basement. I was unable to unthread the elbow in all these cases, mainly because I could not get a good sized pipe wrench on the elbow and tank replacement was necessary.

Well, I’ve rattled on at some length about a tank that has become very popular and one of the more major improvements I have seen in my years in our industry. Next time, I will write briefly about something that they won’t do in my opinion and I will then move on to a different subject.

We’ve had some up and down weather here in Michigan with torrential-type rains, and our grass is nice and green so we can keep on mowing. As this is written in early September we have gotten a cooldown and daytime highs are in the 60s with lows in the mid 40s — fall feels like it has arrived. My favorite football team, the University of Michigan Wolverines, is doing poorly. I hope your team is doing better.

For more John Schmitt columns, visit www.thedriller.com/schmitt.

Report Abusive Comment