When peak demand requirements of a water system exceed the performance capability of a well, additional storage is called for. There are two common approaches. The first is to pump from the well into a non-pressurized storage tank and use a booster pump with a pressure tank to provide the system pressure. The second is to provide more storage in the pressure tank(s). This can be done by using a larger pressure tank than would normally be needed, using more than one pressure tank or by maximizing the available storage in an existing tank.

The latter can be accomplished by spreading the turn-on/turn-off differential of the pressure switch beyond the normal 20-psi setting, by lowering the on/off settings of the pressure switch and leaving the differential at 20 psi, or by lowering the tank pre-charge pressure. An undesirable side effect of spreading the differential or lowering the range is that the water pressure fluctuations in the house may become objectionable.

How to determine the drawdown of a captive air pressure tank at differentials other than 20 psi - The drawdown capacity of a captive air pressure tank is determined by a formula known as Boyle's Law. In a nutshell, Boyle's law states that the drawdown of a pressure tank depends on the range of on and off pressures the tank goes through during the fill and drawdown cycles. In a typical residential water system, the pump is controlled by a pressure switch with a turn-on setting of 20, 30 or 40 psi, and a turn-off pressure of 20 pounds higher. Although pressure switches come with a factory-set differential of 20 psi, they are adjustable. You can adjust the turn-on pressure leaving the differential fixed at 20 psi, you can adjust the differential leaving the turn-on pressure alone, or you can change both.

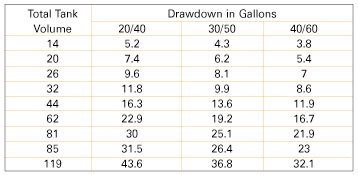

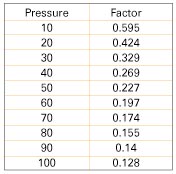

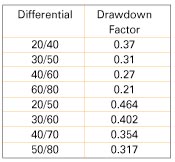

To determine the drawdown at wider differentials and lower settings, use the following formulas and the information presented in Figure 2. These formulas are a derivation of Boyle's law. Figure 3 depicts some commonly used drawdown factors.

Formula 1 (for captive-air tanks without a pre-charge): DD = (CIF - COF) x TTV

Formula 2 (for pre-charged tanks): DD = 1 - (COF / PCF) x TTV

Where DD = drawdown in gallons

CIF = cut-in factor (from figure 2)

COF = cut-out factor (from figure 2)

PCF = pre-charge factor (from figure 2)

TTV = total tank volume in gallons

Note - It is the generally accepted practice to use the CIF as the PCF in pre-charged tank calculations.

In reality, the tank pre-charge is set a couple pounds below the cut-in pressure, so the pre-charge factor will be a slightly larger number than we used in this example. Extrapolating from the numbers in Figure 2, a pre-charge factor of 0.348 would be close. As an exercise, repeat the preceding calculation using this pre-charge factor. Figure 3 shows drawdown factors for commonly used pressure differentials.

Maximizing performance by adjusting tank air pressure vs. turn-on setting or differential - If your goal is to maximize the water available from the combination of pump and pressure tank, the best way may be to keep the pressure switch differential at 20 psi and lower the tank pre-charge to 10 psi below the pressure switch cut-in pressure. In this way, when the system demand exceeds the performance of the pump/well, the tank will continue to deliver stored water after the system pressure drops to and below the pump cut-in pressure. If you have 20 gallons of drawdown between 30 and 50 psi, you will have another approximately 10 more gallons between 20 psi and 30 psi. The exact amount can be determined by using the Boyle's law formulas above. Again, check with the tank manufacturer to make sure you are not exceeding the maximum acceptance factor for your tank.

Spreading the differential and lowering the tank pre-charge are techniques suitable for situations where the peak demand exceeds the performance of the pump by a 20 percent to 30 percent. When the excess demand is larger, you are best to add additional pressure tanks or use a non-pressurized storage tank and re-pressurize the system with a booster pump/pressure tank combination, which is the subject of next month's article. 'Til then ... .

ND

Report Abusive Comment